AIES matches the methodology and processes to Dynamics 365 in the cloud to help you scale and implement efficient manufacturing processes. Our Avanade Intelligent Enterprise Solutions (AIES) is an industry-focused business process library, which fuses together the products, assets and knowledge of Accenture, Avanade and the Microsoft ecosystems. Scale your processes with Avanade Intelligent Enterprise Solutions Accelerate your innovation, growth, and resilience by bringing Dynamics 365 manufacturing capabilities together with Azure, Microsoft 365, and Microsoft Power Platform.

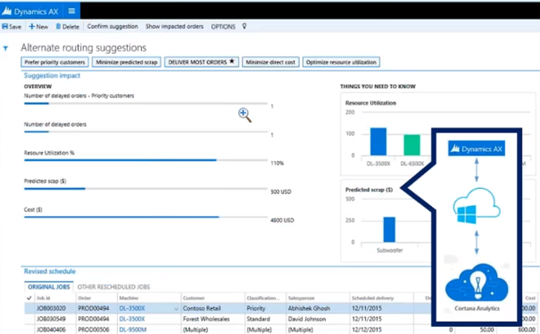

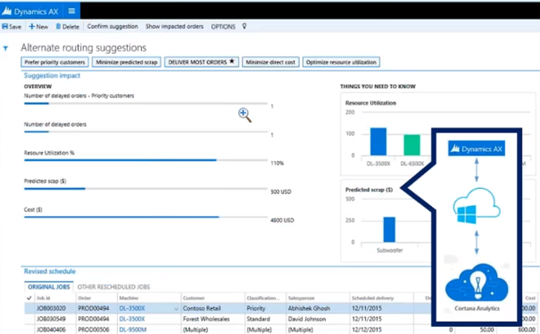

Advanced subcontracting processes allow you to dynamically load balance your resources with vendor resources and improve flow, while optimizing cost through your manufacturing operations. Enhance your solution with Microsoft Cloud for Manufacturing. Enterprise-scale master data synchronization provides a backbone of harmonized processes throughout complex global supply chains.  User productivity is increased by tailoring key user scenarios to optimized flows. Advanced vendor management improves vendor collaboration and helps assess vendor performance. Production tool management provides insight into availability, cost and the current state of your manufacturing tools. It also integrates to various subsystems like automated warehouses or third-party logistics providers. Advanced warehouse management individually models your in-house logistics processes and implements scanner-based material flow throughout the shop floor. Flexible price calculation enables you to simulate and calculate the right prices for every product and market. Supply chain efficiency for best-in-class material flow and collaboration processes is achieved through portal, electronic data interchange and business intelligence technologies, as well as support for specific industry standards. Our deep knowledge of Dynamics 365 is enhanced with our own industry-focused business solutions: We develop a personalized approach based on the appropriate mix of make-to-stock, make-to-order, configure-to-order and engineer-to-order processes. Our solutions drive efficiencies, improve capacity and boost revenues to help you predict and lead in your market. Our approach integrates sales, operations and service functions into a single, intuitive system and provides innovative solutions designed for enhanced employee engagement and customer experiences. The answer? Avanade’s intelligent business applications for manufacturing based on Microsoft Dynamics 365. But the barriers to their usefulness are all too common: siloed operations, unconnected systems and poor insight. Artificial intelligence and machine learning models can help define the next steps in this process transformation and predict the projected outcomes of alternative lines of action. To measure your current market performance and related trends and correlations, you must find ways to collect and analyze information from myriad sources, both structured and unstructured, and then mine that data. Keeping up with these changes is hard, and that can hamper your ability to transform and scale your manufacturing business. And new technologies like composite and robotic material manufacturing are disrupting traditional product development and supply processes. Product innovation cycles are accelerating rapidly. The global economy is growing at an ever-increasing pace. Account for changing customer demand, material availability, and capacity constraints across multiple sites and warehouses with the Planning Optimization Add-in.Predict and lead in your market with intelligent manufacturing solutions Performing production planning in real time. Support all your manufacturing strategies, including make to stock, make to order, configure to order, and engineer to order.

User productivity is increased by tailoring key user scenarios to optimized flows. Advanced vendor management improves vendor collaboration and helps assess vendor performance. Production tool management provides insight into availability, cost and the current state of your manufacturing tools. It also integrates to various subsystems like automated warehouses or third-party logistics providers. Advanced warehouse management individually models your in-house logistics processes and implements scanner-based material flow throughout the shop floor. Flexible price calculation enables you to simulate and calculate the right prices for every product and market. Supply chain efficiency for best-in-class material flow and collaboration processes is achieved through portal, electronic data interchange and business intelligence technologies, as well as support for specific industry standards. Our deep knowledge of Dynamics 365 is enhanced with our own industry-focused business solutions: We develop a personalized approach based on the appropriate mix of make-to-stock, make-to-order, configure-to-order and engineer-to-order processes. Our solutions drive efficiencies, improve capacity and boost revenues to help you predict and lead in your market. Our approach integrates sales, operations and service functions into a single, intuitive system and provides innovative solutions designed for enhanced employee engagement and customer experiences. The answer? Avanade’s intelligent business applications for manufacturing based on Microsoft Dynamics 365. But the barriers to their usefulness are all too common: siloed operations, unconnected systems and poor insight. Artificial intelligence and machine learning models can help define the next steps in this process transformation and predict the projected outcomes of alternative lines of action. To measure your current market performance and related trends and correlations, you must find ways to collect and analyze information from myriad sources, both structured and unstructured, and then mine that data. Keeping up with these changes is hard, and that can hamper your ability to transform and scale your manufacturing business. And new technologies like composite and robotic material manufacturing are disrupting traditional product development and supply processes. Product innovation cycles are accelerating rapidly. The global economy is growing at an ever-increasing pace. Account for changing customer demand, material availability, and capacity constraints across multiple sites and warehouses with the Planning Optimization Add-in.Predict and lead in your market with intelligent manufacturing solutions Performing production planning in real time. Support all your manufacturing strategies, including make to stock, make to order, configure to order, and engineer to order.

♦ Automate and improve resource managementĪcross any workload, and track and manage your workforce, machines, and tools, using integrated Dynamics 365 Field Service. Respond quickly to last-minute customer requests and changes, and take advantage of new business opportunities to stay ahead of your competition.ĭrive smarter processes and operations by using the Internet of Things (IoT), AI, machine learning, and mixed reality to optimize people, processes, and equipment. Microsoft Dynamics for Manufacturing boosts efficiency to effectively manage production, including production orders, bills of materials, supply planning, and capacity requirements planning.

0 kommentar(er)

0 kommentar(er)